|

Batscan is the world's only Battery Monitoring System that fully complies with the European Low

Voltage Directive (LVD) and the EN60950 safety standard for information technology equipment,

even when connected to a high voltage UPS battery.

The purpose of these standards is principally to protect buildings from fire and people from an electrical shock. However, since the batteries are a very critical component in a backup-power system, extreme caution must be taken when connecting additional wires to them.

Therefore, Batscan is taking this one step further by implementing the same level of protection for the batteries. This guarantees that the monitoring system only can detect battery faults, not cause them.

A true Monitoring System

Inherently by design, Batscan cannot control the battery, the charger or the load. This is not a limitation,

it is an essential requirement for a true monitoring system, that by definition it should be allowed to observe only,

without any means of influencing the result.

Any technical system can fail, and most do - sooner or later. When this happens with a device that

controls the battery, an independent monitoring system will prove its value.

Advanced technology

Distinctive features that characterizes a Batscan as the best choice for monitoring large UPS batteries,

includes but are not limited to:

- It is Safe, for people AND batteries.

- It measures all battery cells Simultaneously.

- It is Fast enough to capture short events.

It seems obvious that this should be basic requirements for all Battery Monitoring Systems, but facts are that

no other system feature any of these characteristics, even less all three of them.

It poses a great engineering challenge to combine these requirements into one single system, at a reasonable cost. It cannot

be done like a standard "text book" data acquisition system. Fortunately, with the advanced signal processing technology that is

available today, it is possible.

Protective resistor

To comply with the first vital requirement Batscan uses a large resistor for all connections to the battery cells.

The resistor´s value is 2MΩ (2 000 000 ohm), and it is rated for 10kV (10 000 Volt) over voltage pulses.

This resistor creates a high impedance circuit with very low current capability, which is essential for safety. (However, the

resistor also imposes some undesired side effects in terms of adding noise and making the system susceptible to EMI, which

cannot be handled by a simple monitoring system.)

The resistor is integrated in the battery connectors with a crimp splice for the measuring leads and a FAST-ON connector that

pairs with a tab-washer fitted on the cell terminals.

| Low Current |

High Current |

|

| |

|

|

|

|

| |

|

| Current limiting resistor |

|

|

The wiring harness in a Batscan system impose no risk for hazards, the resistor limits the maximum short circuit current to

250µA (0.00025 A) at 500V, this current is not enough to cause a spark, discharge the battery or hurt a person.

Intelligent measuring modules

The real workhorses in the Batscan system are the measuring modules. They use a dual processor Digital Signal Processing (DSP)

technique to restore the DC signal from the batteries with high speed oversampling digital to analog conversions followed by

a property filtering algorithm. An internal transformer with reinforced isolation (6kV test voltage) separates the analog

side from the communication bus.

| Low Voltage |

High Voltage |

Digital post-processing

& bus interface |

Analog front-end with

high speed sampling |

| Temperature |

|

Connections

to Battery |

| Network In |

| Network Out |

| |

→ |

← |

|

| |

6kV Test Voltage |

|

There are two types of measuring modules, one that measures up to 8 cell (or block voltages) via the protective resistors,

and one that measures up to 4 string currents via hall-effect current transducers.

Along with that, each module also measures internal on-board temperature and allows for up to 8 external temperature sensors to be connected.

All modules are powered from the communication bus.

Modular design

The modular design allows for flexible configuration and system layout. The modules can be mounted directly

on the battery, inside the wire conduits, grouped together in larger enclosures or even be placed in a 19" rack cabinet.

For large UPS batteries, a common configuration is wall mounted IP65 enclosures with 4 to 10 modules placed next

to each battery string.

The modules are interconnected with modular cable and plugs, for longer distances a high quality DeviceNet cable

is used.

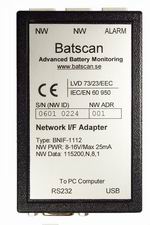

BNIF: PC Interface

Adapter

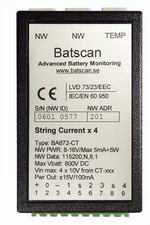

BA642: 4-channel

Current measuring

module

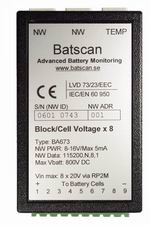

BA643: 8-channel

Voltage measuring

module

|